Gold medal for Sport Group at the Diamond League

55 Diamond League events (the most) have been held on Sport Group’s Rekortan & Polytan tracks

With over 50 years experience, Sport Group’s Rekortan and Polytan are the market leaders in Diamond League quality tracks

32% of all Diamond League events have taken place on Sport Group tracks

25% of all World Athletics certified tracks are from Sport Group (the most)

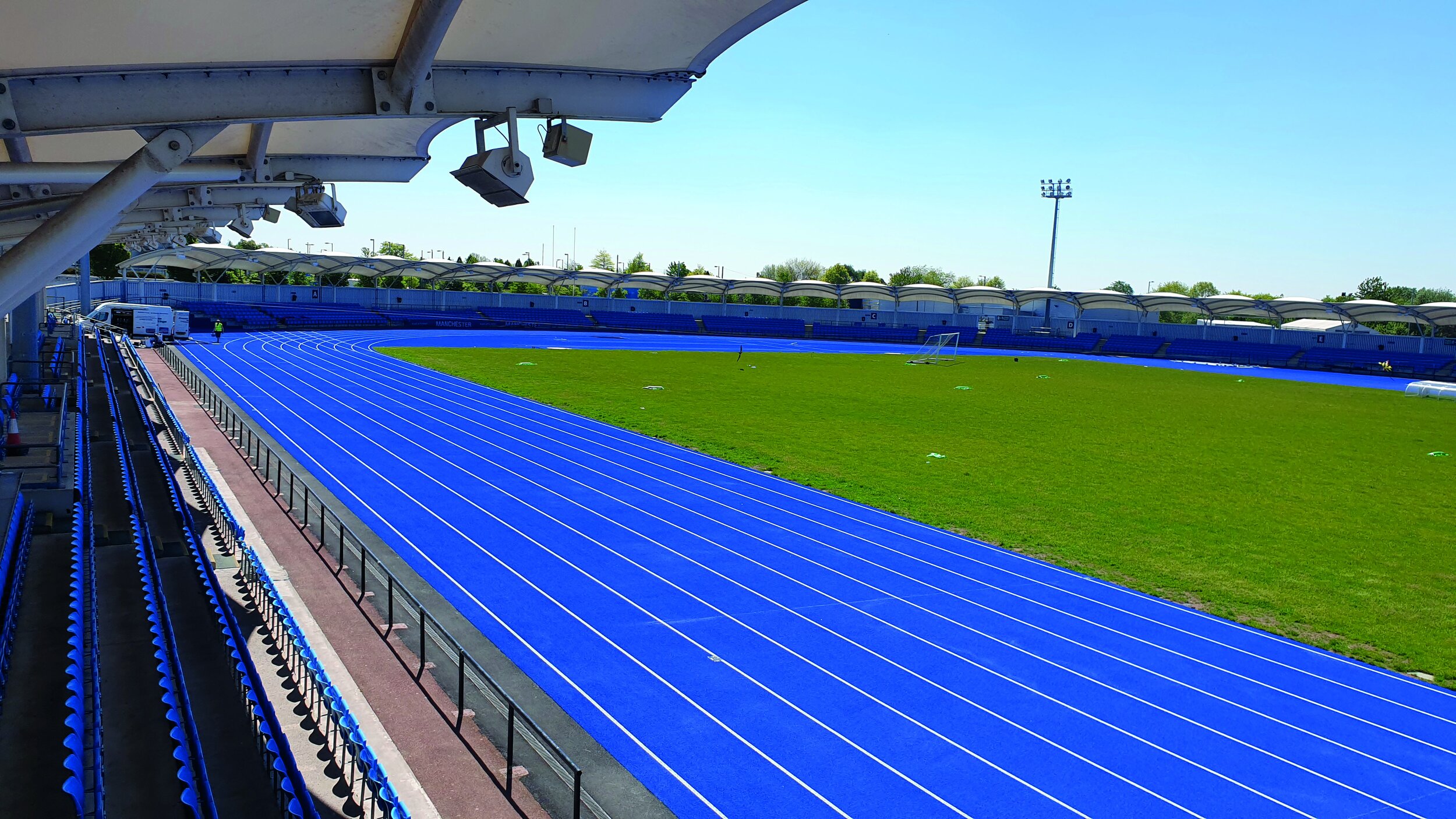

Our tracks are used at iconic stadiums – Bislett Stadium, Oslo and the Olympic Stadium, Stockholm. And new exciting stadiums - Prince Moulay Abdellah Stadium, Rabat and Qatar Sports Club, Doha

WHAT MAKES REKORTAN & POLYTAN TRACKS DIAMOND LEAGUE QUALITY?

The world’s greatest track athletes gather at The Diamond League, a series of athletics meetings that sits in the top-tier of the World Athletics competitions. At such an elite level, every millisecond and millimeter counts which is why records only count on certified tracks so that everyone is competing on an even and fair surface.

It takes decades to master the design and build of these top-of-the-line tracks. They are big projects, and each market has its own complexities and challenges. Since track systems are only 13-15mm, the asphalt layer is crucial to the flatness of the surface. Such small tolerances allowed means that a high level of precision is required.

Sport Group’s Rekortan and Polytan have been trusted by the most venues around the world for over 50 years and provide 25% of all World Athletics certified tracks. And no other company has held more Diamond League events on their tracks than us.

WORLD ATHLETICS CLASS 1 AND CLASS 2 CERTIFICATIONS

World Athletics certifies athletics track facilities as either Class 1 or Class 2. To achieve this certification the track must be made with a World Athletics approved track system.

“It takes decades to master the design and build of these top-of-the-line tracks. They are big projects, and each market has its own complexities and challenges.”

Class 1 Certified Tracks

This is the premier standard and is required for hosting major global athletics events.

The testing is completed onsite by an independent accredited testing lab. The test comprises of a field report and a measurement report.

The field test (in-situ testing) report measures track thickness, flatness, force reduction (energy dissipation), vertical deformation (how spongy the track is) and other key requirements. An elite track cannot have softer or harder parts, as any tiny differences are amplified by elite runners at the top of their game.

The testing will measure the athletics track system thickness in over 200 places using a FloorTest tool, which inserts 3 long needles through the track system until they touch the underlying asphalt or concrete base. The testing is very demanding; a minimum of 90% of the total track system thickness must be at least 90% of the product’s approved thickness.

This means on a 13mm system, 90% of the track must be at least 11.7mm. The margin of error across 10,000 m2 is just 1.3mm!

Track smoothness is tested with a 4m long straight edge which is pulled across the entire track in all directions. This is extremely important, as athletes running at full pace must have complete confidence that the track surface is consistent and uniform underfoot.

Also, as many tracks are impervious to water, an undulation can create puddles.

For the installer, the most challenging places to meet the standards are where the track meets the D areas (where the throwing events are), and the transition areas where there is a change in slope.

The field testing can be expensive, so this is typically only done at venues that are going to host major competitions. These events generally require significant additional infrastructure as well, which can include a full-sized warm-up track for World Championships, Olympic Games & other major global events such as the 2018 Asian Games and the 2019 SEA Games which are also Sport Group (Polytan/Rekortan) tracks.

The second part of Class 1 testing is the Track and Field Facilities Measurement Report. This confirms the dimensional accuracy of the line marking, the track gradient, and associated areas such as throwing event landing sectors, comply with World Athletics requirements. This is crucially important as athletics is so precise; facilities must be standardized around the world, so it is fair for all.

Class 2 Certified Tracks

Class 2 tracks must have approved products and provide a conforming Track and Field Facilities Measurement Report. Class 2 tracks do not require the field report. This certification standard is designed to provide a more cost-effective solution for facilities that are not hosting major international competition.

The Class 1 and Class 2 reports are sent to the World Athletics technical committee for approval and they issue the certificate upon satisfactory review of all necessary supporting documentation and reports. A certification fee must be paid to World Athletics for each facility.